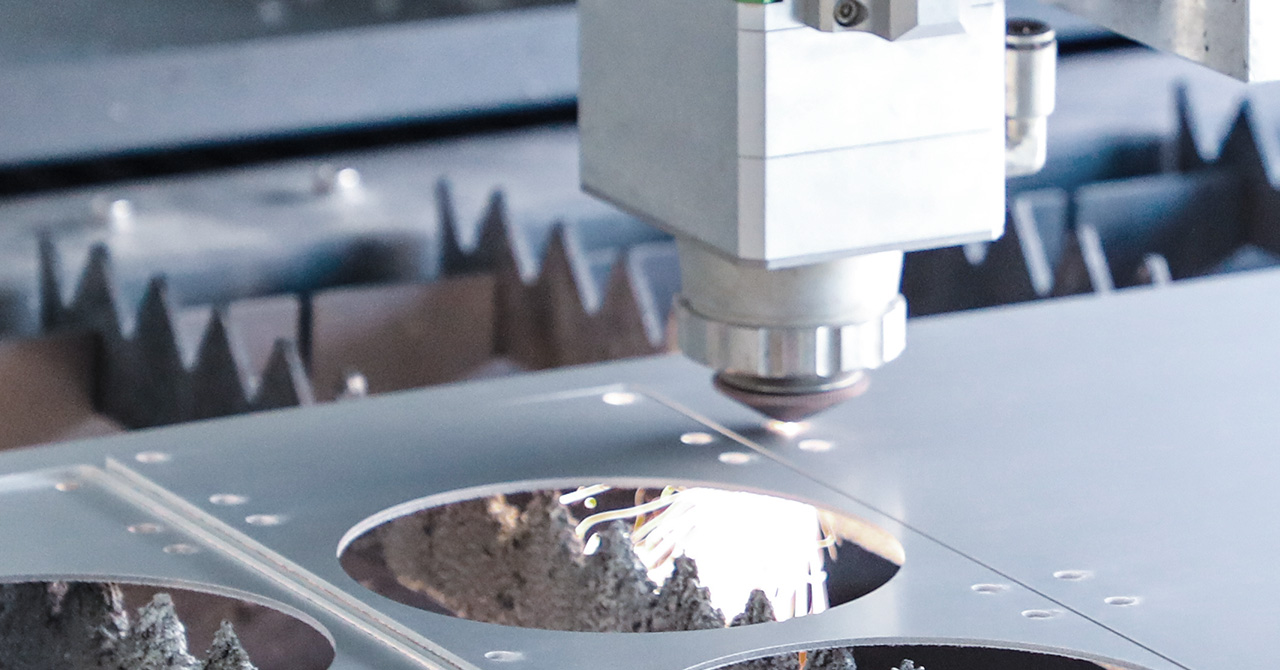

Laser cutting is a cutting process that can be used to cut metal and non-metal materials with different material thicknesses. The guided, shaped and bundled laser beam lays the foundation for this. After it hits the workpiece, it heats the material to melt or evaporate. All laser power is concentrated at a point that is usually less than half a millimeter in diameter. If the heat input at this location is more than the heat lost due to thermal conduction, the laser beam will completely penetrate the material and the cutting process will begin. In other processes, heavy tools exert huge external forces on the plate, and the laser beam completes its work without contact. Therefore, the tool itself will not be worn, and the workpiece will not be deformed or damaged.

Copyright© 2021 Dongguan Golden nine Laser Technology Co., Ltd. Powered by www.300.cn

Copyright© 2021 Dongguan Golden nine Laser Technology Co., Ltd.

搜索

Language

Language