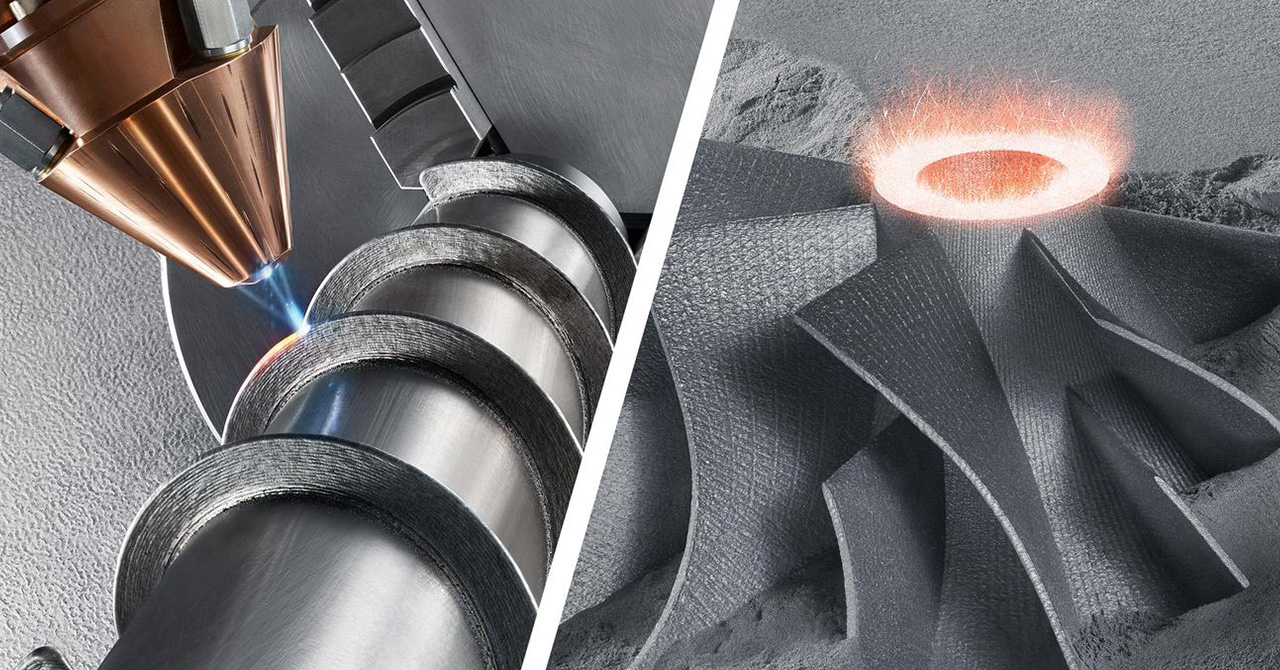

When using scanning welding, a movable mirror [1] is used to guide the processing beam. The laser beam is guided by the angle change of the mirror [4]. This creates a processing area [3] in which welding operations can be carried out with a high degree of dynamics and precision. The size of the processing area depends on the working distance and the deflection angle of the laser beam. The processing speed and the spot diameter on the workpiece depend on the imaging characteristics of the mirror group, the incident angle of the laser beam, the beam quality and the material. Through the movement of an auxiliary lens system [2], the focus can also be moved with extremely high dynamics in the Z-axis direction, so that the three-dimensional workpiece can be processed completely without moving the laser head or the workpiece. Since the offset movement speed of the laser beam is very fast, there is almost no non-production time, and the laser can be operated in nearly 100% of the production time.

Scan welding

Views:

Previous :

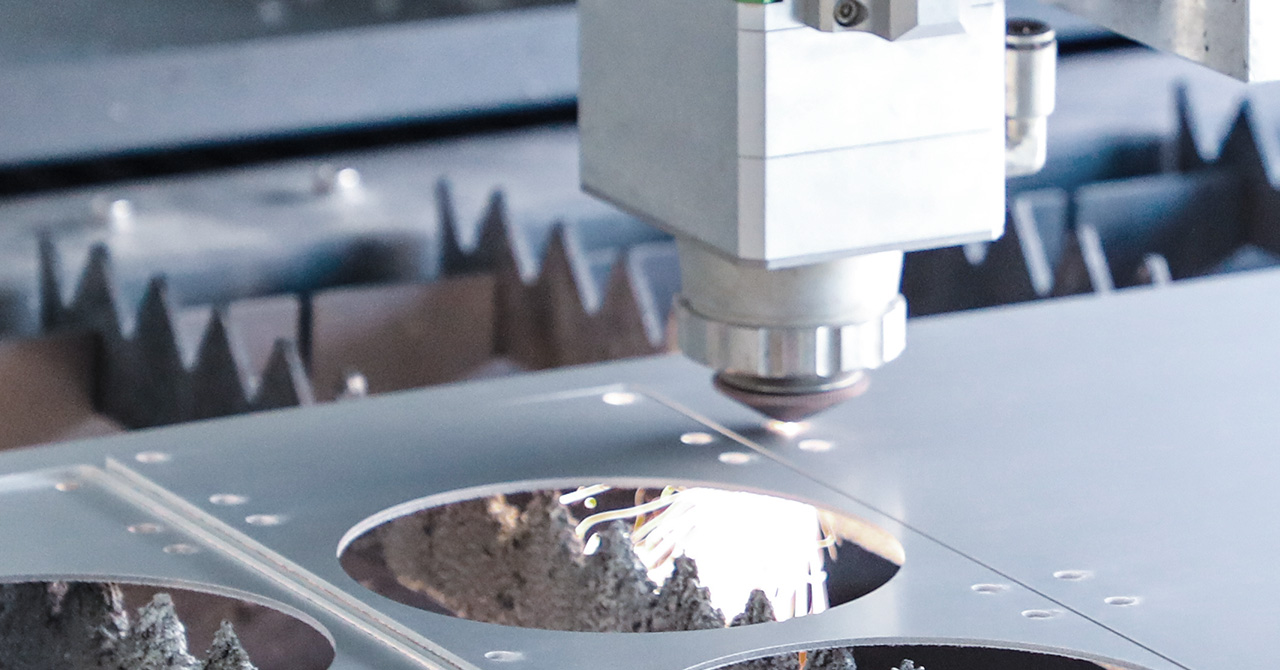

laser cutting

Next :

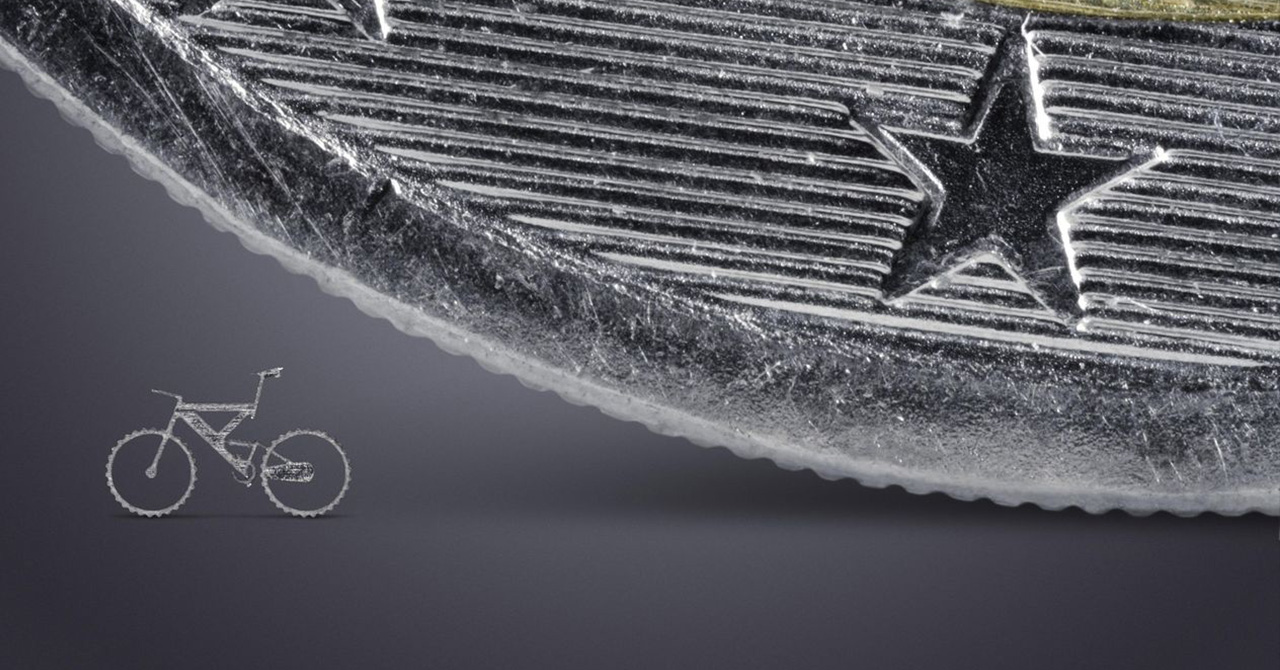

Micromachining

Previous :

laser cutting

Next :

Micromachining

Copyright© 2021 Dongguan Golden nine Laser Technology Co., Ltd. Powered by www.300.cn

Copyright© 2021 Dongguan Golden nine Laser Technology Co., Ltd.

搜索

Language

Language